The Thermal Systems Transition Study is a large-scale study initiated by the UO Climate Action Plan (CAP) 2.0.

Completed in the Fall of 2022, the Thermal Systems Transition study identifies and analyzes options for transitioning the University of Oregon campus from its existing steam heating distribution system to a system that brings the University closer to achieving the greenhouse gas (GHG) emissions reduction goals outlined in CAP 2.0.

The university’s district heating system in Eugene is the focal point of Climate Action Plan 2. The UO’s Design and Construction office commissioned the engineering firm Affiliated Engineers, Inc. (AEI), a major engineering firm with experience overhauling campus heating infrastructure, to identify options for transitioning from our natural gas-fired boilers and steam distribution system to a system that meets current resiliency and reliability standards, achieves science-based emissions reduction targets, and improves efficiency. During Summer 2022, the university was presented with potentially feasible options.

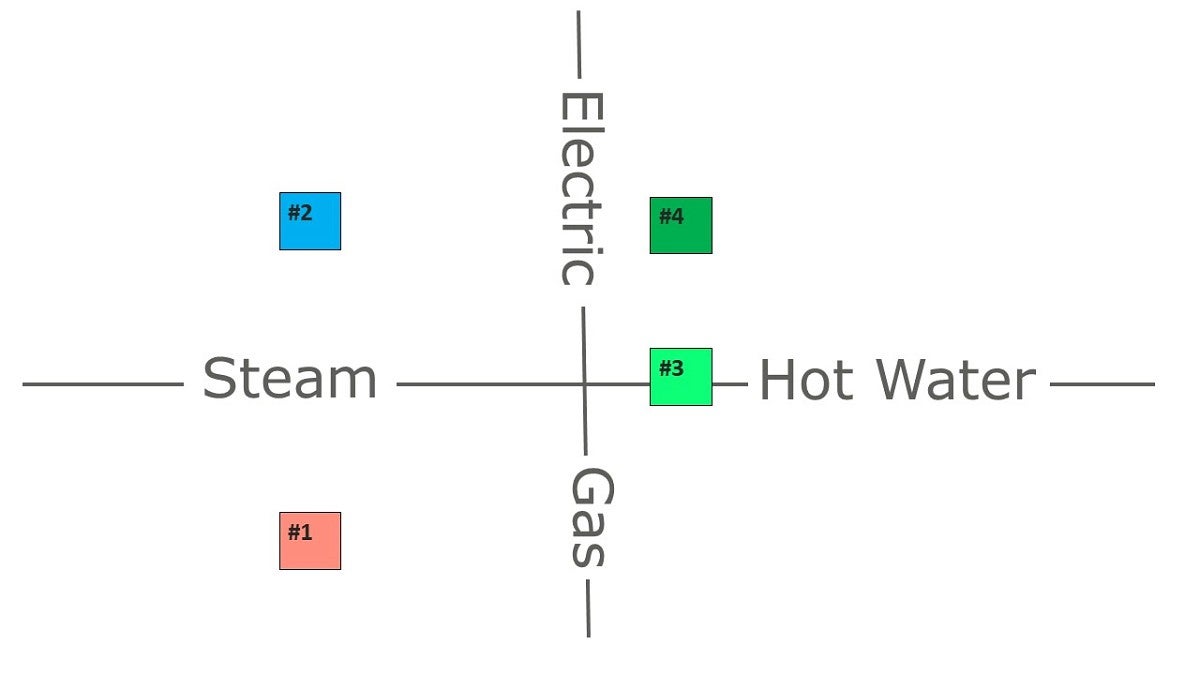

UO’s Thermal System Transition Options

The study presents several conceptual options for heating systems that could facilitate the achievement of UO’s CAP 2.0 goals. Descriptions of the options identified by AEI are provided below in broad strokes along with the rationale and potential ramifications of each.

When commissioning AEI with this study, the Office of Sustainability specified that any proposal must accomplish at least a 50% emissions reduction target, but aim for 80%. The baseline for calculating these percentages reflects the GHG emissions levels associated with “Business as Usual:” a centralized steam heating plant and steam heating distribution throughout campus.

Options Under Consideration

1. Systems As Usual

Maintain current boilers and steam heat distribution system

In this scenario, UO’s existing steam heating and chilled water systems and infrastructure continue operating as they did in 2022. All equipment is replaced in kind as it reaches the end of its useful life, with the exception of equipment with a lifespan greater than 30 years. This option does not require conversion to a new thermal system, and would therefore cause minimal disruption to campus life.

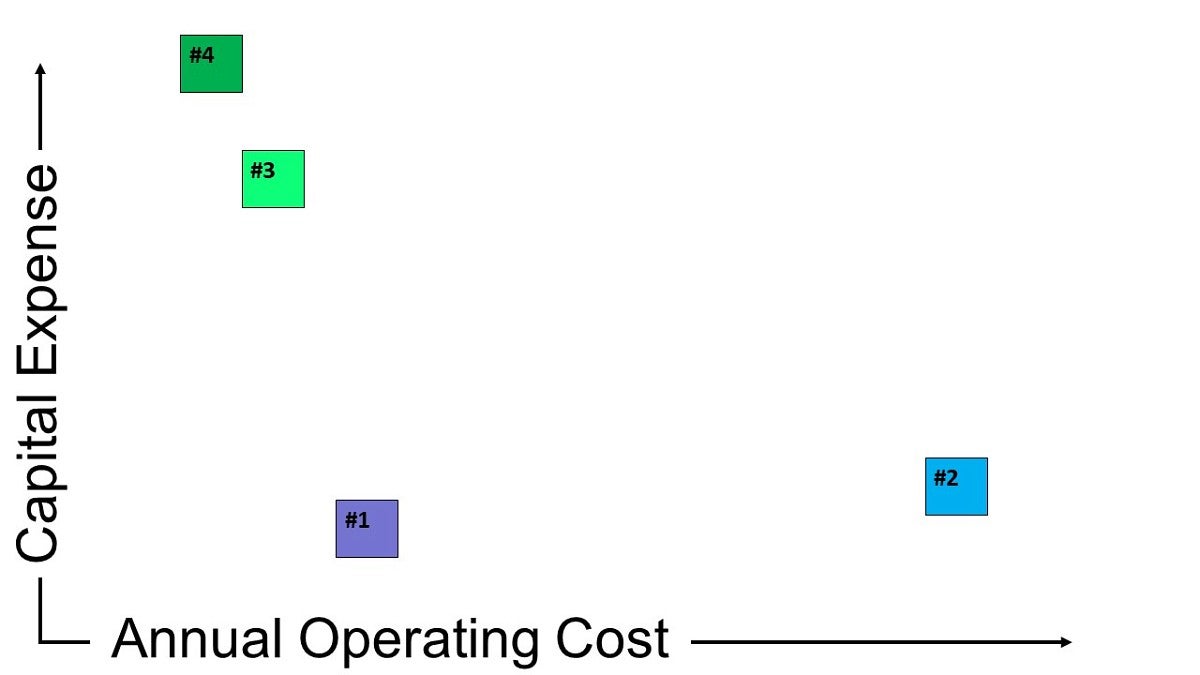

The Business as Usual option does not require an initial capital investment or infrastructure spending, and it is fueled by relatively inexpensive natural gas. As such, it presents the lowest lifecycle cost for the systems analyzed. But the existing system is not efficient from a carbon emissions standpoint and does not meet the University’s GHG emissions reduction targets.

2. Electrode Bolier

Transition from gas-fired to electric boilers. Keep steam distribution system.

This option switches the fuel source for a majority of the campus heating load from natural gas to electricity. An electrode steam boiler replaces the existing boiler in the central heating plant (though existing natural gas boilers remain in place as backup). Option 2 does not require conversion to a new thermal system, and would therefore cause minimal disruptions to campus life.

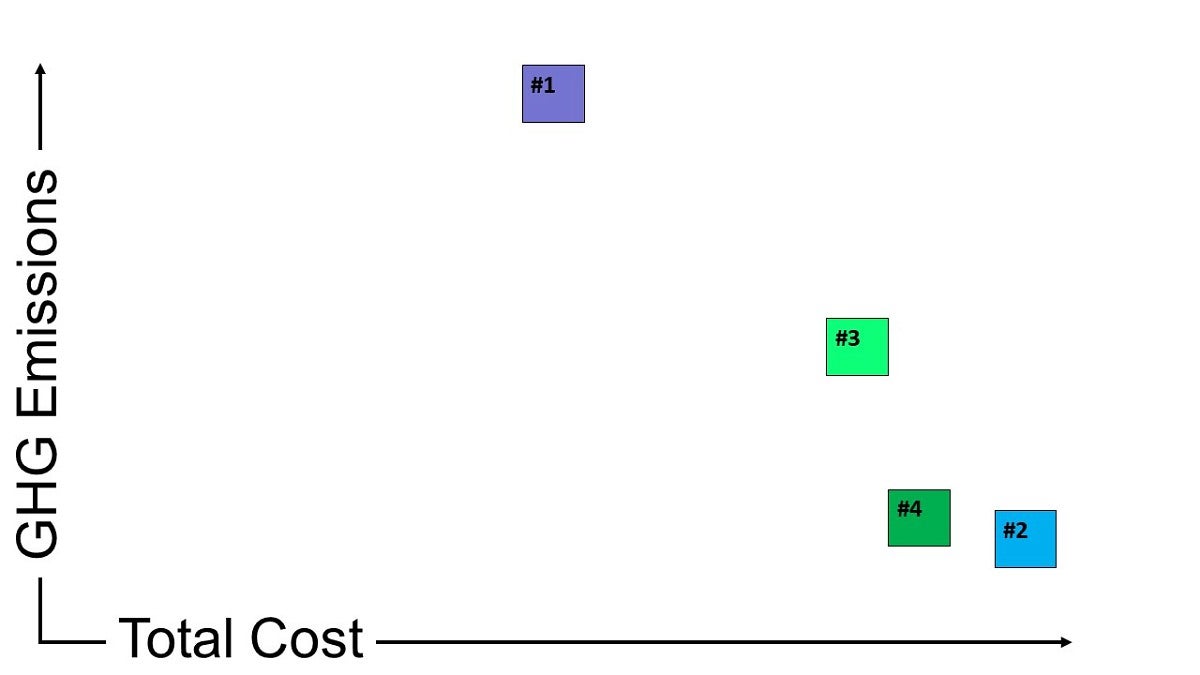

The initial expense of installing an electrode steam boiler in UO’s existing plant is modest, but the cost of electricity is high. This option yields the most radical reduction in GHG emissions, surpassing the 80% reduction threshold.

3. Heat Recovery Chiller

Add heat recovery chillers. Transition from steam to hot water heat distribution system.

In this scenario, the campus steam heating system is converted to a hot water distribution system and two heat recovery chillers are added. The construction and renovation required by this option makes it substantially disruptive to campus life.

The capital cost burden of this option is high due to distribution system construction and building conversions. In option 3, utility costs are reduced by 30%, and GHG emissions are reduced by over 50%.

4. Heat Recovery Chiller, Alternate Source

Add electric heat pumps and heat recovery chillers. Transition from steam to hot water heat distribution system.

This option is similar to option 3, but incorporates an alternate heat source to augment thermal generation: the Millrace industrial water right component. This scenario requires a new hot water pumping system. This option’s construction and utility costs are roughly the same as for option 3, but it provides greater GHG reductions. Option 4 reduces baseline GHG emissions by over 80%.

Comparing of Options

There are a variety of ways to compare the feasible options to one another, and each has it's advantages and disadvantages. The following charts provide comparative information on a few of the key issues at hand - energy source and distribution, emissions reduction, and costs.

Task Force Recommendation

The UO Thermal Systems Task Force is responsible for reviewing the engineering firm’s report, new state emissions reduction regulations, EWEB and NW Natural resource plans and price projections. This project is further complicated by the national and regional energy transition now underway. Task Force members are analyzing price, reliability, and other impacts resulting from massive electrification of the transportation and heating sectors. The final recommendation to the president will use the criteria listed below to evaluate the two critical decisions at the heart of this issue – electricity or natural gas as primary energy source and steam or hot water as distribution medium.

- Emissions reductions

- Technical feasibility

- Fiscal responsibility

- Disruption to campus

- Resilience and reliability

- Campus community feedback